Journal de bord

Jour 1 & 2 : Documentation des capteurs

Fonctionnement des capteurs :

Infrarouge :

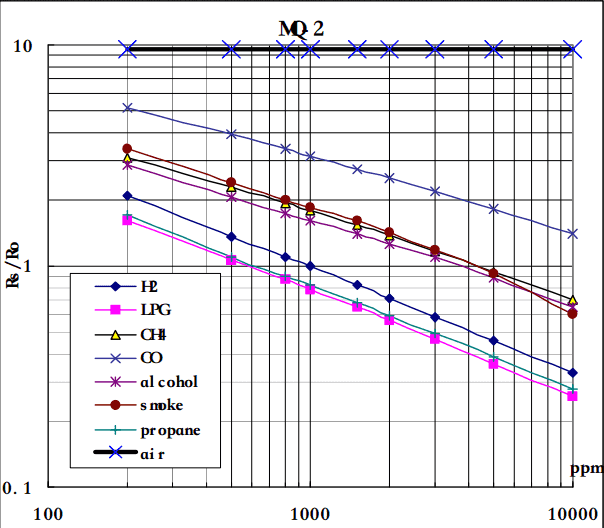

Grove Capteur de gaz MQ2 (Seeed) : https://wiki.seeedstudio.com/Seeed_Gas_Sensor_Selection_Guide/

Informations générales et code

- Gaz cible : GPL, butane, propane, méthane, alcool, hydrogène, fumée

- Classe : Electrochimique

- Champs d'application : Sécurité et application domestique/au travail

- Plage de détection : GPL & Propane : 200-5000 ppm, Butane : 300-5000 ppm, Méthane : 5000-20000 ppm, H2 : 300-5000 ppm, Alcool : 100-2000ppm

- Tension de fonctionnement : 5V

- Interface : Analogique

Code capteur MQ2

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float sensorValue;

sensorValue = analogRead(A0);

sensor_volt = sensorValue/1024*5.0;

Serial.print("sensor_volt = ");

Serial.print(sensor_volt);

Serial.println("V");

delay(1000);

}

Grove Capteur de gaz MQ9 :

https://wiki.seeedstudio.com/Grove-Gas_Sensor-MQ9/

Informations générales et code

- Gaz cibles : GPL, CO, CH4

- Classe : Electrochimique

- Caractéristiques : grand champ de détection, stable et longue durée de vie, haute sensibilité

- Champs d'application : Sécurité et application domestique/au travail et dans l'industrie

- Plage de détection : GPL & Propane : 200-20000 ppm

- Tension de fonctionnement : 5V

- Interface : Analogique

Code MQ9

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float sensorValue;

sensorValue = analogRead(A0);

sensor_volt = sensorValue/1024*5.0;

Serial.print("sensor_volt = ");

Serial.print(sensor_volt);

Serial.println("V");

delay(1000);

}

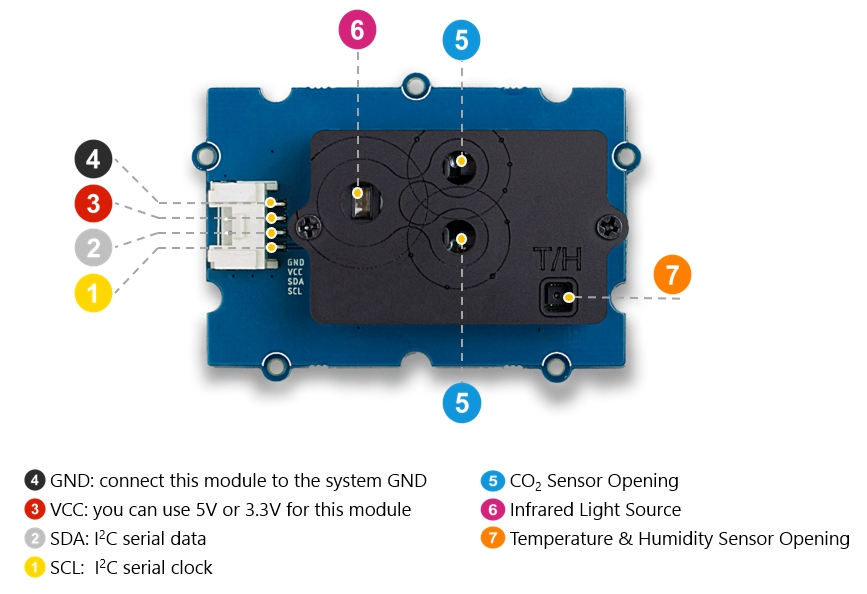

Capteur Grove CO2, Température & humidité SCD30 : https://wiki.seeedstudio.com/Grove-CO2_Temperature_Humidity_Sensor-SCD30/

Le capteur SCD30 est un capteur de dioxyde de carbone de haute précision, basé sur le Sensirion SCD30. En plus de la technologie de mesure infrarouge non dispersive (NDIR) pour la détection du CO2, le SCD30 intègre des capteurs d'humidité et de température Sensirion sur le même module de capteur.

Information générales et code

- Plage de détection : 0-40000 ppm

- Précision : entre 400-10000ppm± (30 ppm + 3 %)

- Calibrage : Lors de la première activation, une période d'au moins 7 jours est nécessaire pour que l'algorithme puisse trouver son jeu de paramètres initiaux pour l'ASC. Le capteur doit être exposé à l'air frais pendant au moins 1 heure chaque jour. Pendant cette période également, le capteur ne doit pas être débranché de l'alimentation électrique, sinon la procédure de recherche des paramètres d'étalonnage est interrompue et doit être recommencée depuis le début. Les paramètres calculés avec succès sont stockés dans la mémoire non volatile du SCD30, ce qui fait qu'après un réinitialisé, les paramètres trouvés précédemment pour l'ASC sont toujours présents.

Code SCD30

#include "SCD30.h"

#if defined(ARDUINO_ARCH_AVR)

#pragma message("Defined architecture for ARDUINO_ARCH_AVR.")

#define SERIAL Serial

#elif defined(ARDUINO_ARCH_SAM)

#pragma message("Defined architecture for ARDUINO_ARCH_SAM.")

#define SERIAL SerialUSB

#elif defined(ARDUINO_ARCH_SAMD)

#pragma message("Defined architecture for ARDUINO_ARCH_SAMD.")

#define SERIAL SerialUSB

#elif defined(ARDUINO_ARCH_STM32F4)

#pragma message("Defined architecture for ARDUINO_ARCH_STM32F4.")

#define SERIAL SerialUSB

#else

#pragma message("Not found any architecture.")

#define SERIAL Serial

#endif

void setup()

{

Wire.begin();

SERIAL.begin(115200);

SERIAL.println("SCD30 Raw Data");

scd30.initialize();

}

void loop()

{

float result[3] = {0};

if(scd30.isAvailable())

{

scd30.getCarbonDioxideConcentration(result);

SERIAL.print("Carbon Dioxide Concentration is: ");

SERIAL.print(result[0]);

SERIAL.println(" ppm");

SERIAL.println(" ");

SERIAL.print("Temperature = ");

SERIAL.print(result[1]);

SERIAL.println(" ℃");

SERIAL.println(" ");

SERIAL.print("Humidity = ");

SERIAL.print(result[2]);

SERIAL.println(" %");

SERIAL.println(" ");

SERIAL.println(" ");

SERIAL.println(" ");

}

delay(2000);

}

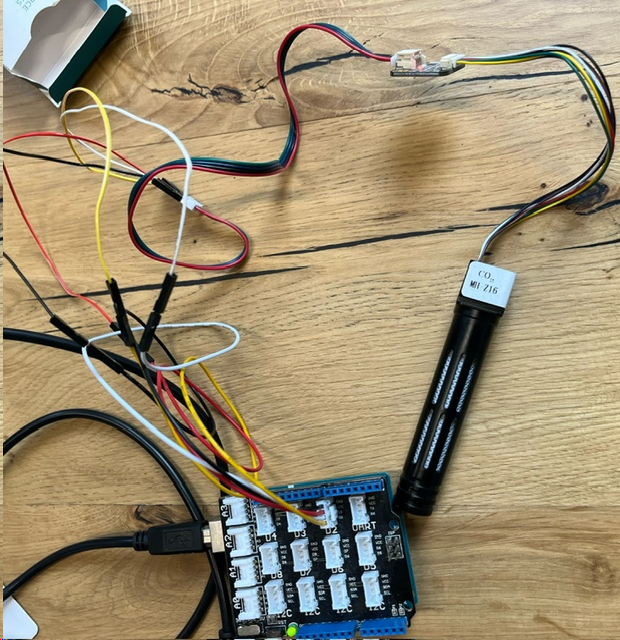

Grove Capteur de gaz CO2 MH-Z16 : https://wiki.seeedstudio.com/Grove-CO2_Sensor/

Le capteur MH-Z16 est un capteur de CO2 infrarouge non-dispersif(NDIR)

Informations générales et code

- Gaz cible : CO2

- Caractéristiques : grand champ de détection, stable et longue durée de vie, haute sensibilité

- Champs d'application : Surveillance de la CVC et de la qualité de l'air, de la sécurité des processus industriels et des processus de production agricole et animale

- Plage de détection : CO2 : 0-2000 ppm

- Plage de résolution : 1 ppm

- Précision : 200 ppm

- Température de fonctionnement : 0 à 50℃

- Humidité de fonctionnement : 0 % ~ 90 % HR

- Température de stockage : - 20-60 ℃

- Tension de fonctionnement : 4,5V à 6V

- Interface : UART

Code MH-Z16

/*

This test code is write for Arduino AVR Series(UNO, Leonardo, Mega)

If you want to use with LinkIt ONE, please connect the module to D0/1 and modify:

// #include <SoftwareSerial.h>

// SoftwareSerial s_serial(2, 3); // TX, RX

#define sensor Serial1

*/

#include <SoftwareSerial.h>

SoftwareSerial s_serial(2, 3); // TX, RX

#define sensor s_serial

const unsigned char cmd_get_sensor[] =

{

0xff, 0x01, 0x86, 0x00, 0x00,

0x00, 0x00, 0x00, 0x79

};

unsigned char dataRevice[9];

int CO2PPM;

void setup()

{

sensor.begin(9600);

Serial.begin(9600);

Serial.println("get a 'g', begin to read from sensor!");

Serial.println("********************************************************");

Serial.println();

}

void loop()

{

if(dataRecieve())

{

Serial.print(" CO2: ");

Serial.print(CO2PPM);

Serial.println("");

}

delay(10000);

}

bool dataRecieve(void)

{

byte data[9];

int i = 0;

//transmit command data

for(i=0; i<sizeof(cmd_get_sensor); i++)

{

sensor.write(cmd_get_sensor[i]);

}

Serial.flush();

//begin reveiceing data

if(sensor.available())

{

while(sensor.available())

{

for(int i=0;i<9; i++)

{

data[i] = sensor.read();

}

}

}

for(int j=0; j<9; j++)

{

Serial.print(data[j],HEX);

Serial.print(" ");

}

Serial.println("");

// First calculate then validate the check sum as there is no point in proceeding if the packet is corrupted. (code inspired by datasheet algorithm)

byte checksum = 0 ;

for(int j=1; j<8; j++)

{

checksum += data[j];

}

checksum=0xff-checksum;

checksum+=1;

if (checksum != data[8])

{

Serial.println("Error checksum");

return false;

}

// Then check the start byte to make sure response is what we were expecting

if ( data[0] != 0xFF )

{

Serial.println("Error start byte");

return false;

}

// Then check the command byte to make sure response is what we were expecting

if ( data[1] != 0x86 )

{

Serial.println("Error command");

return false;

}

CO2PPM = (int)data[2] * 256 + (int)data[3];

return true;

}

Le code ci-dessus fonctionne et affiche la valeur du CO2 présent dans la pièce. Cette valeur augmente lorsqu'on souffle sur le capteur.

Capteur de CO2 infrarouge Grove Gravity V1.1 : https://circuitdigest.com/microcontroller-projects/interfacing-gravity-inrared-co2-sensor-to-measure-carbon-dioxyde-in-ppm

Code Gravity

int sensorIn = A4;

#include <SPI.h>

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

#define SCREEN_WIDTH 128 // OLED display width, in pixels

#define SCREEN_HEIGHT 64 // OLED display height, in pixels

// Declaration for SSD1306 display connected using software SPI (default case):

#define OLED_MOSI 9

#define OLED_CLK 10

#define OLED_DC 11

#define OLED_CS 12

#define OLED_RESET 13

Adafruit_SSD1306 display(SCREEN_WIDTH, SCREEN_HEIGHT,

OLED_MOSI, OLED_CLK, OLED_DC, OLED_RESET, OLED_CS);

void setup(){

Serial.begin(9600);

// Set the default voltage of the reference voltage

analogReference(DEFAULT);

display.begin(SSD1306_SWITCHCAPVCC);

display.clearDisplay();

display.display();

}

void loop(){

//Read voltage

int sensorValue = analogRead(sensorIn);

// The analog signal is converted to a voltage

float voltage = sensorValue*(5000/1024.0);

if(voltage == 0)

{

Serial.println("Fault");

}

else if(voltage < 400)

{

Serial.println("preheating");

}

else

{

int voltage_diference=voltage-400;

float concentration=voltage_diference*50.0/16.0;

// Print Voltage

Serial.print("voltage: ");

Serial.print(voltage);

Serial.println("mv");

//Print CO2 concentration

Serial.print("CO2 Concentration: ");

Serial.print(concentration);

Serial.println("ppm");

display.setTextSize(2);

display.setTextColor(WHITE);

display.setCursor(18,43);

display.println("CO2");

display.setCursor(63,43);

display.println("(PPM)");

display.setTextSize(2);

display.setCursor(28,5);

display.println(concentration);

display.display();

display.clearDisplay();

}

delay(2000);

}

Capteur CO2 MHZ19B avec M5STACK : https://github.com/toripoyo/M5Stack_MH-Z19B_Digital/blob/master/README.md

Code MHZ-19B

#include <M5Stack.h>

const uint8_t kCommandLen = 9;

const uint8_t kResponseLen = 9;

const uint8_t kReadCommand[kCommandLen] = {0xFF, 0x01, 0x86, 0x00, 0x00, 0x00, 0x00, 0x00, 0x79};

const uint8_t kResetCommand[kCommandLen] = {0xFF, 0x01, 0x87, 0x00, 0x00, 0x00, 0x00, 0x00, 0x78};

// BackGround Picture Data

extern const unsigned short BGPicture[];

// Function Define

void drawPPMVal(uint16_t);

void drawBlueScreen(String);

void setup()

{

M5.begin();

Serial2.begin(9600);

M5.Lcd.setTextColor(TFT_WHITE);

M5.Lcd.setTextFont(4);

// Calibration

M5.update();

if (M5.BtnB.isPressed())

{

Serial2.write(kResetCommand, kCommandLen);

drawBlueScreen("Resetting...");

delay(5000);

M5.Power.reset();

}

}

void loop()

{

uint8_t response[kResponseLen] = {};

// Read Current ppm

Serial2.write(kReadCommand, kCommandLen);

Serial2.readBytes(response, kResponseLen);

// resnponse is ok

if (response[0] == 0xFF && response[1] == 0x86)

{

uint16_t meas_PPM = (256 * response[2]) + response[3];

drawPPMVal(meas_PPM);

delay(1000);

}

else

{

drawBlueScreen("Invalid Response!");

delay(3000);

M5.Power.reset();

}

}

// ---------------------------------------------------------------------

// Draw Blue Screen

void drawBlueScreen(String s)

{

M5.Lcd.fillScreen(TFT_BLUE);

M5.Lcd.setTextColor(TFT_WHITE);

M5.Lcd.setTextSize(1);

M5.Lcd.drawString(s, 0, 100);

}

// Draw Now Data

void drawPPMVal(uint16_t ppm)

{

const uint16_t x_offset = 40;

static uint16_t ppm_old = 0;

if (ppm != ppm_old)

{

ppm_old = ppm;

M5.Lcd.setTextColor(TFT_WHITE);

M5.Lcd.setTextSize(1);

M5.Lcd.drawString("CO2 Meter", 0, 0);

M5.Lcd.setTextSize(2);

M5.Lcd.drawString("ppm", 220, 160);

if (ppm >= 1500)

{

M5.Lcd.setTextColor(TFT_RED);

M5.Lcd.drawString("Warning!", 5, 160);

}

else if (ppm >= 1000 && ppm < 1500)

{

M5.Lcd.setTextColor(TFT_ORANGE);

}

else if (ppm >= 500 && ppm < 1000)

{

M5.Lcd.setTextColor(TFT_GREEN);

}

else if (ppm < 500)

{

M5.Lcd.setTextColor(TFT_BLUE);

}

M5.Lcd.fillRect(30, 50, 240, 100, TFT_BLACK);

M5.Lcd.drawNumber(ppm, 40, 60, 6);

}

}

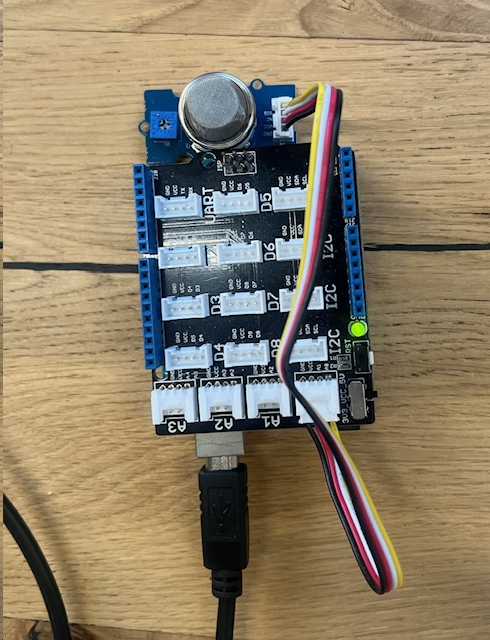

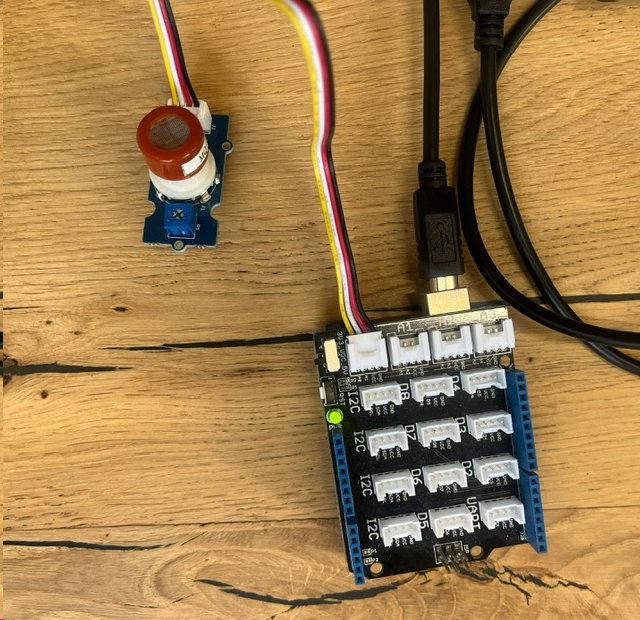

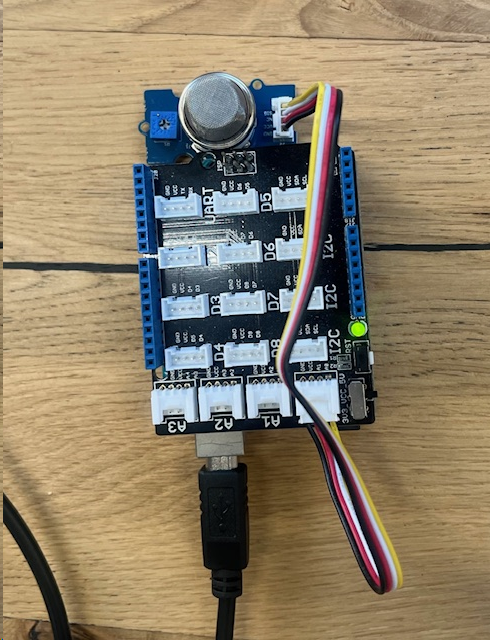

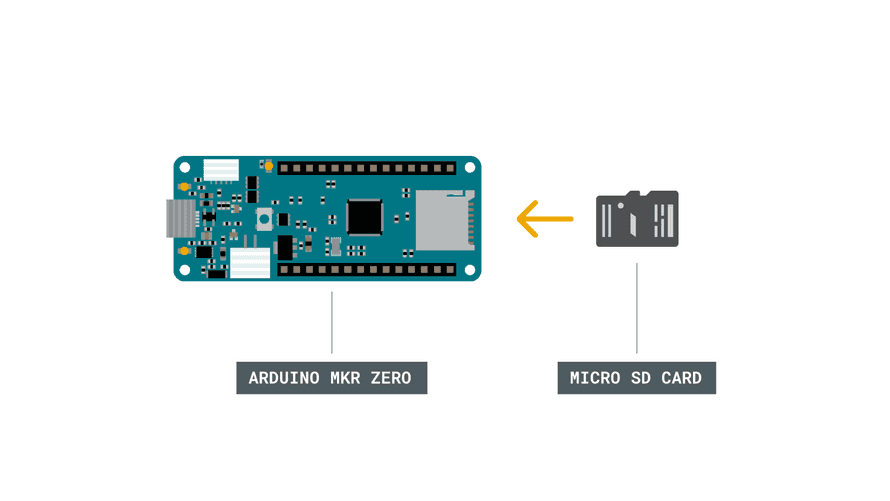

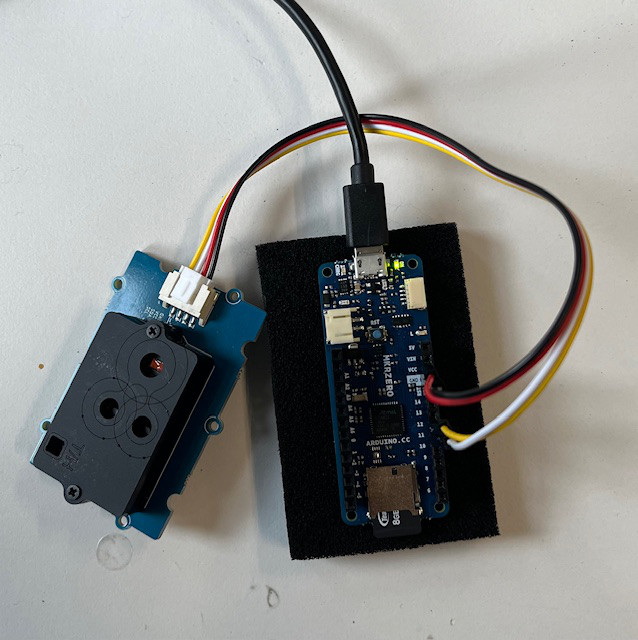

Jour 3 & 4 : Création d'un data logger MQ2

Création d'un Data Logger : https://docs.arduino.cc/tutorials/mkr-zero/mkr-zero-data-logger/

Détails

On commence par connecter la carte SD à la carte arduino MKRZero. On obtient 3 séries de chiffres pour les 3 sorties. On récupère ensuite la carte SD, les données se trouvent alors dans un fichier DATA.txt.

lien pour rectifier l'erreur "Compilation error no such file or directory" : https://www.programmingelectronics.com/no-such-file-error/#:~:text=If%20you%20don't%20see,%3E%20Include%20Library%20%3E%20Manage%20Libraries.

Code Data logger

/*!

* @file DHT.h

*

* This is a library for DHT series of low cost temperature/humidity sensors.

*

* You must have Adafruit Unified Sensor Library library installed to use this

* class.

*

* Adafruit invests time and resources providing this open source code,

* please support Adafruit andopen-source hardware by purchasing products

* from Adafruit!

*

* Written by Adafruit Industries.

*

* MIT license, all text above must be included in any redistribution

*/

#ifndef DHT_H

#define DHT_H

#include "Arduino.h"

/* Uncomment to enable printing out nice debug messages. */

//#define DHT_DEBUG

#define DEBUG_PRINTER \

Serial /**< Define where debug output will be printed. \

*/

/* Setup debug printing macros. */

#ifdef DHT_DEBUG

#define DEBUG_PRINT(...) \

{ DEBUG_PRINTER.print(__VA_ARGS__); }

#define DEBUG_PRINTLN(...) \

{ DEBUG_PRINTER.println(__VA_ARGS__); }

#else

#define DEBUG_PRINT(...) \

{} /**< Debug Print Placeholder if Debug is disabled */

#define DEBUG_PRINTLN(...) \

{} /**< Debug Print Line Placeholder if Debug is disabled */

#endif

/* Define types of sensors. */

static const uint8_t DHT11{11}; /**< DHT TYPE 11 */

static const uint8_t DHT12{12}; /**< DHY TYPE 12 */

static const uint8_t DHT21{21}; /**< DHT TYPE 21 */

static const uint8_t DHT22{22}; /**< DHT TYPE 22 */

static const uint8_t AM2301{21}; /**< AM2301 */

#if defined(TARGET_NAME) && (TARGET_NAME == ARDUINO_NANO33BLE)

#ifndef microsecondsToClockCycles

/*!

* As of 7 Sep 2020 the Arduino Nano 33 BLE boards do not have

* microsecondsToClockCycles defined.

*/

#define microsecondsToClockCycles(a) ((a) * (SystemCoreClock / 1000000L))

#endif

#endif

/*!

* @brief Class that stores state and functions for DHT

*/

class DHT {

public:

DHT(uint8_t pin, uint8_t type, uint8_t count = 6);

void begin(uint8_t usec = 55);

float readTemperature(bool S = false, bool force = false);

float convertCtoF(float);

float convertFtoC(float);

float computeHeatIndex(bool isFahrenheit = true);

float computeHeatIndex(float temperature, float percentHumidity,

bool isFahrenheit = true);

float readHumidity(bool force = false);

bool read(bool force = false);

private:

uint8_t data[5];

uint8_t _pin, _type;

#ifdef __AVR

// Use direct GPIO access on an 8-bit AVR so keep track of the port and

// bitmask for the digital pin connected to the DHT. Other platforms will use

// digitalRead.

uint8_t _bit, _port;

#endif

uint32_t _lastreadtime, _maxcycles;

bool _lastresult;

uint8_t pullTime; // Time (in usec) to pull up data line before reading

uint32_t expectPulse(bool level);

};

/*!

* @brief Class that defines Interrupt Lock Avaiability

*/

class InterruptLock {

public:

InterruptLock() {

#if !defined(ARDUINO_ARCH_NRF52)

noInterrupts();

#endif

}

~InterruptLock() {

#if !defined(ARDUINO_ARCH_NRF52)

interrupts();

#endif

}

};

#endif

2 ème Code Data Logger

#include <SPI.h>

#include <SD.h>

const int chipSelect = SDCARD_SS_PIN;

void setup() {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial) {

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

}

void loop() {

// make a string for assembling the data to log:

String dataString = "";

// read three sensors and append to the string:

for (int analogPin = 0; analogPin < 3; analogPin++) {

int sensor = analogRead(analogPin);

dataString += String(sensor);

if (analogPin < 2) {

dataString += ",";

}

}

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}On ajoute un capteur de CO2 MQ2 :

Explication et codes

lien youtube du montage et code : youtube.com/watch?v=8DQQDpaZYj8

Lien du github associé : https://github.com/harshkzz/Arduino-with-MQ2-Sensor-and-Serial-Monitor/blob/main/MQ-2-sensor-library-master.zip

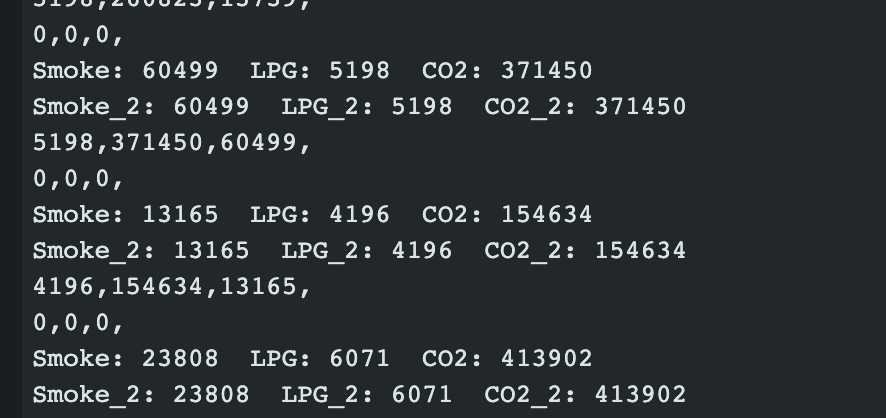

2 codes qui donnent les mêmes résultats :

Code Data logger + capteur MQ2

#include<MQ2.h>

#define PIN A0

MQ2 mq2(PIN);

void setup() {

Serial.begin(9600);

mq2.begin();

}

void loop() {

int lpg = mq2.readLPG();

int co = mq2.readCO();

int smo = mq2.readSmoke();

Serial.print("Smoke: ");

Serial.print(smo);

Serial.print(" LPG: ");

Serial.print(lpg);

Serial.print(" CO2: ");

Serial.println(co);

delay(2000);

}2ème code data logger + capteur MQ2

/*

Scheduled Datalogger

Demonstrates how to log temperature and humidity sensor

reading and time using a MKRZero, then you can plot the

graph of the temperature and humidity in a romm during

the whole day!

This example code is in the public domain

Parts required:

1 DHT22 temperature and humidity sensor

1 MKR protoshield

created by Arturo Guadalupi <a.guadalupi@arduino.cc>

3 Nov 2016

*/

#include <SD.h>

#include <RTCZero.h>

#include <DHT.h>

#define DHTPIN 7

#define DHTTYPE DHT22

DHT dht(DHTPIN, DHTTYPE);

const int chipSelect = SS1;

unsigned long previousTime;

int loadDataCheck; //Checks if data needs to be loaded

RTCZero rtc;

/* Change these values to set the current initial time */

const byte seconds = 50;

const byte minutes = 44;

const byte hours = 17;

/* Change these values to set the current initial date */

const byte day = 1;

const byte month = 9;

const byte year = 16;

// the setup function runs once when you press reset

// or power the board

void setup() {

// initialize digital pin LED_BUILTIN as an output.

pinMode(LED_BUILTIN, OUTPUT);

Serial.begin(9600);

Serial.println("DataLogger Example:");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

return;

}

Serial.println("card initialized.");

//When power is supplied to the DHT22 sensor,

//don't send any instruction to the sensor

//within one second to pass unstable status

delay(1000);

Serial.println("Initializing DHT");

dht.begin();

Serial.println("Initializing RTC");

rtc.begin();

rtc.setTime(hours, minutes, seconds);

rtc.setDate(day, month, year);

rtc.setAlarmTime(0, 0, 0);

rtc.enableAlarm(rtc.MATCH_SS); //alarm attached every minute

rtc.attachInterrupt(dataCheck);

loadDataCheck=0;

previousTime=millis();

Serial.println("System ready...");

}

// the loop function runs over and over again forever

void loop() {

unsigned long currentTime=millis();

if ((currentTime-previousTime)>5000)

{

digitalWrite(LED_BUILTIN, HIGH); // turn the LED on

delay(100); // wait for a bit

digitalWrite(LED_BUILTIN, LOW); // turn the LED off

previousTime=millis();

}

if (loadDataCheck) logData();

}

void dataCheck(){

loadDataCheck=1;

}

void logData(void) {

float humidity = dht.readHumidity();

float temperature = dht.readTemperature();

String dataString = "";

dataString += "Temperature: " + String(temperature) + " C" + "\t" + "Humidity: " + String(humidity) + "%\t" + "Time: " + getTime();

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the Serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

loadDataCheck=0;

}

String getTime(void) {

String returnString = "";

if (rtc.getHours() < 10)

returnString += "0" + String(rtc.getHours());

else

returnString += String(rtc.getHours());

returnString += ":";

if (rtc.getMinutes() < 10)

returnString += "0" + String(rtc.getMinutes());

else

returnString += String(rtc.getMinutes());

returnString += ":";

if (rtc.getSeconds() < 10)

returnString += "0" + String(rtc.getSeconds());

else

returnString += String(rtc.getSeconds());

return returnString;

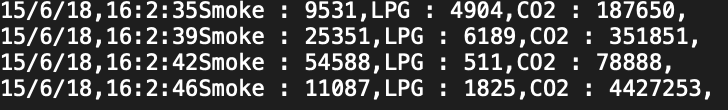

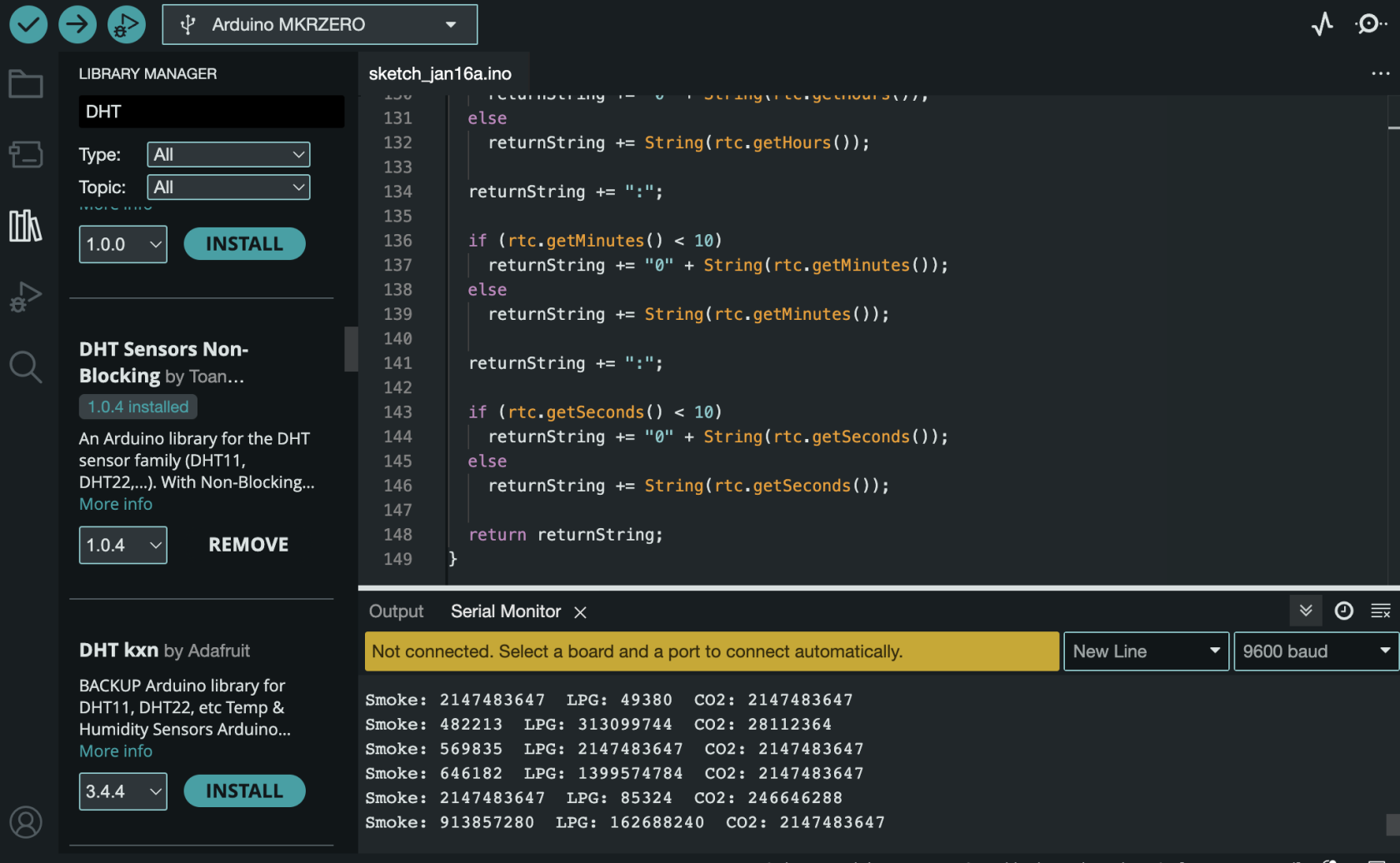

}On obtient les valeurs de fumée, LPG et CO2. Cependant, il faut calibrer le capteur, il n'y a pas d'unités.

screen

Ensuite on essaye d'enregistrer les valeurs du capteur sur la carte SD :

On utilise le code suivant qui est un mix des codes précédents :

Code pour enregistrer les valeurs du capteur sur la carte SD

#include <SPI.h>

#include <SD.h>

#include<MQ2.h>

const int chipSelect = SDCARD_SS_PIN;

#define PIN A0

MQ2 mq2(PIN);

void setup() {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

}

void loop() {

// make a string for assembling the data to log:

String dataString = "";

// read three sensors and append to the string:

int lpg = mq2.readLPG();

int co = mq2.readCO();

int smo = mq2.readSmoke();

Serial.print("Smoke: ");

Serial.print(smo);

Serial.print(" LPG: ");

Serial.print(lpg);

Serial.print(" CO2: ");

Serial.println(co);

delay(2000);

dataString += String(lpg);

dataString += ",";

dataString += String(co);

dataString += ",";

dataString += String(smo);

dataString += ",";

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}Les valeurs s'enregistrent bien à la suite des valeurs aléatoires sur le fichier DATALOG.TXT, j'ai crée un dossier DATALOGCO2 - copie qui ne contient que les valeurs récupérées des capteurs.

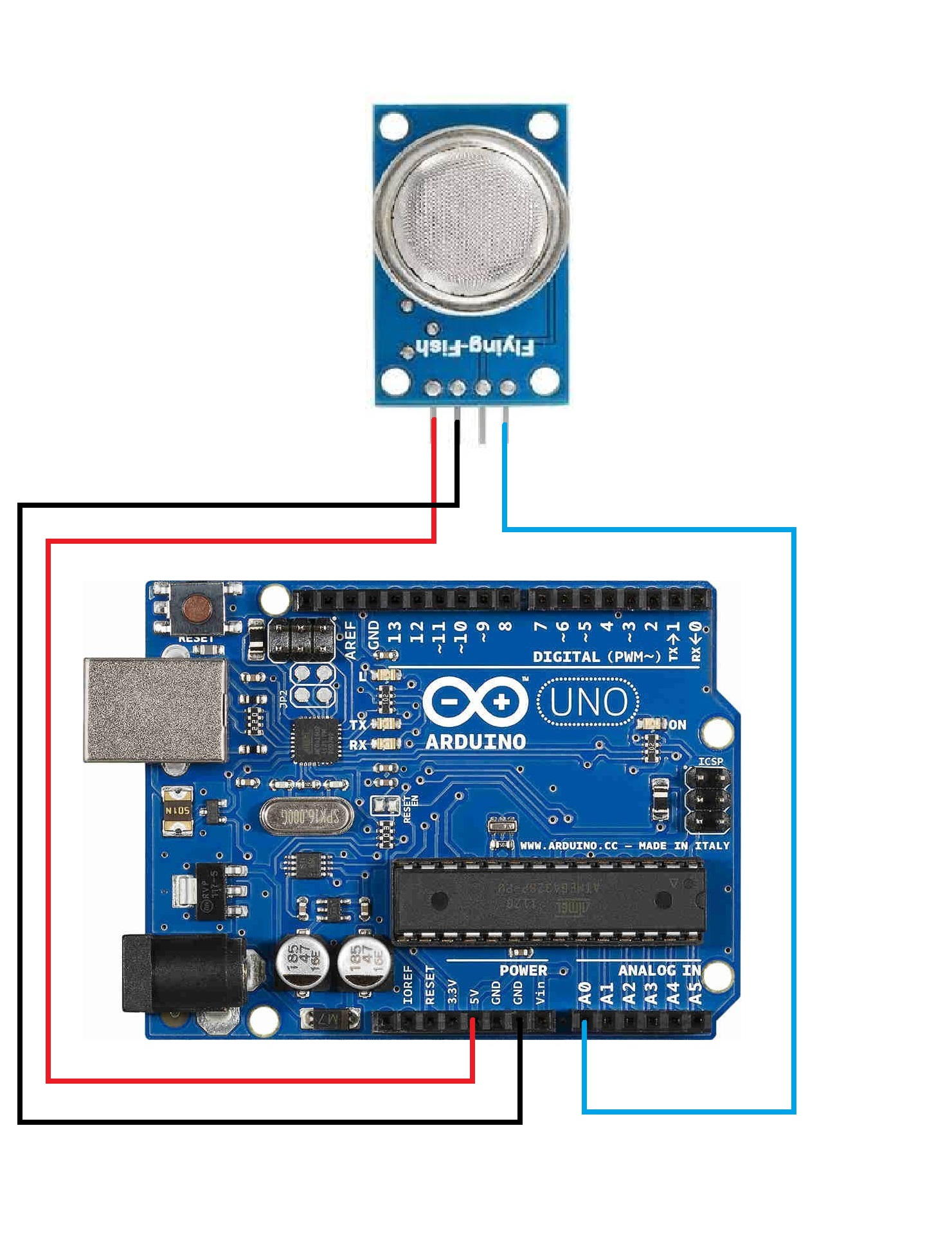

On essaye maintenant de connecter plusieurs capteurs. On connecte deux capteurs MQ2 à une arduino uno. On utilise le code suivant, on récupère las valeurs des deux capteurs.

Code pour connecter plusieurs capteurs Arduino Uno

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float sensorValue;

float sensor_volt2;

float sensorValue2;

sensorValue = analogRead(A0);

sensor_volt = sensorValue/1024*5.0;

sensorValue2 = analogRead(A1);

sensor_volt2 = sensorValue2/10224*5.0;

Serial.print("sensor_volt = ");

Serial.print(sensor_volt);

Serial.println("V");

Serial.print("sensor_volt2 = ");

Serial.print(sensor_volt2);

Serial.println("V");

delay(1000);

}On connecte maintenant les deux capteurs MQ2 à une arduino MKRZero avec le code suivant, on obtient les mêmes valeurs sur les deux lignes, une ligne en plus avec des valeurs qui correspondent peut être au second capteur et une ligne de 0 qui ne correspond à rien. Le fichier sur la carte SD lui ne comporte pas deux lignes avec les mêmes valeurs.

Code pour connecter deux capteurs à une MKRZero

#include <SPI.h>

#include <SD.h>

#include<MQ2.h>

int chipSelect = SDCARD_SS_PIN;

#define PIN A0

#define PIN2 A1

MQ2 mq2(PIN);

MQ2 mq22(PIN2);

void setup() {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

}

void loop() {

// make a string for assembling the data to log:

String dataString = "";

String dataString2 = "";

// read three sensors and append to the string:

int lpg = mq2.readLPG();

int co = mq2.readCO();

int smo = mq2.readSmoke();

Serial.print("Smoke: ");

Serial.print(smo);

Serial.print(" LPG: ");

Serial.print(lpg);

Serial.print(" CO2: ");

Serial.println(co);

delay(2000);

dataString += String(lpg);

dataString += ",";

dataString += String(co);

dataString += ",";

dataString += String(smo);

dataString += ",";

int lpg2 = mq22.readLPG();

int co2 = mq22.readCO();

int smo2 = mq22.readSmoke();

Serial.print("Smoke_2: ");

Serial.print(smo);

Serial.print(" LPG_2: ");

Serial.print(lpg);

Serial.print(" CO2_2: ");

Serial.println(co);

delay(2000);

dataString2 += String(lpg2);

dataString2 += ",";

dataString2 += String(co2);

dataString2 += ",";

dataString2 += String(smo2);

dataString2 += ",";

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

Serial.println(dataString2);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}Code pour créer une horloge RTC, on obtient la date et l'heure : https://docs.arduino.cc/tutorials/generic/simple-rtc/

Code pour créer une horloge

/*

Simple RTC for Arduino Zero and MKR1000

Demonstrates the use of the RTC library for the Arduino Zero and MKR1000

This example code is in the public domain

https://www.arduino.cc/en/Tutorial/SimpleRTC

created by Arturo Guadalupi <a.guadalupi@arduino.cc>

15 Jun 2015

modified

18 Feb 2016

modified by Andrea Richetta <a.richetta@arduino.cc>

24 Aug 2016

*/

#include <RTCZero.h>

/* Create an rtc object */

RTCZero rtc;

/* Change these values to set the current initial time */

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 16;

/* Change these values to set the current initial date */

const byte day = 15;

const byte month = 6;

const byte year = 15;

void setup()

{

Serial.begin(9600);

rtc.begin(); // initialize RTC

// Set the time

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

// Set the date

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

// you can use also

//rtc.setTime(hours, minutes, seconds);

//rtc.setDate(day, month, year);

}

void loop()

{

// Print date...

print2digits(rtc.getDay());

Serial.print("/");

print2digits(rtc.getMonth());

Serial.print("/");

print2digits(rtc.getYear());

Serial.print(" ");

// ...and time

print2digits(rtc.getHours());

Serial.print(":");

print2digits(rtc.getMinutes());

Serial.print(":");

print2digits(rtc.getSeconds());

Serial.println();

delay(1000);

}

void print2digits(int number) {

if (number < 10) {

Serial.print("0"); // print a 0 before if the number is < than 10

}

Serial.print(number);

}On essaye maintenant de rajouter une horloge au data logger avec le code suivant :

On obtient sur la carte SD la date, l'heure et les valeurs du capteur :

Code pour ajouter l'horloge au Data logger

#include <SPI.h>

#include <SD.h>

#include<MQ2.h>

#include <RTCZero.h>

const int chipSelect = SDCARD_SS_PIN;

#define PIN A0

MQ2 mq2(PIN);

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 16;

const byte day = 15;

const byte month = 6;

const byte year = 18;

void setup() {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

// read three sensors and append to the string:

int lpg = mq2.readLPG();

int co = mq2.readCO();

int smo = mq2.readSmoke();

Serial.print("Smoke: ");

Serial.print(smo);

Serial.print(" LPG: ");

Serial.print(lpg);

Serial.print(" CO2: ");

Serial.println(co);

delay(2000);

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString += "Smoke : ";

dataString += String(smo);

dataString += ",";

dataString += "LPG : ";

dataString += String(lpg);

dataString += ",";

dataString += "CO2 : ";

dataString += String(co);

dataString += ",";

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}Exemple de code qui obtient la concentration en ppm grâce au capteur MQ2 en faisant la conversion : https://phmarduino.wordpress.com/2017/09/03/station-de-mesure-les-capteurs-2/

Jour 5 : Création de data logger avec différents capteurs

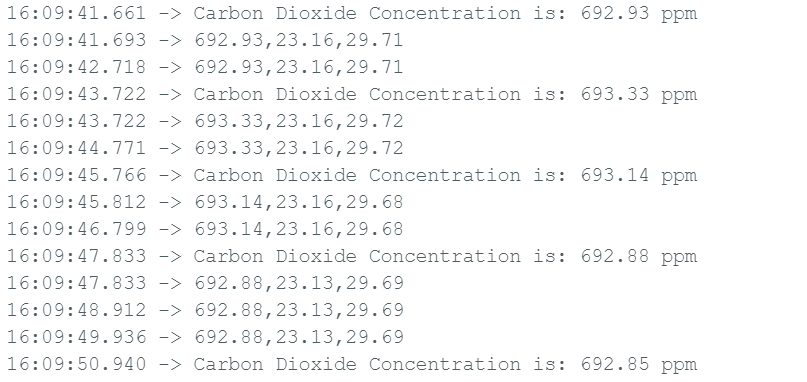

Capteur SCD30:

Détails

Le code suivant permet d'enregistrer les données du capteur sur la carte SD :

Code pour enregistrer les données du capteur sur la carte

#include <SPI.h>

#include <SD.h>

#include <Wire.h>

#include "SCD30.h"

float result[3] = {0}; // sensor readings

const int chipSelect = SDCARD_SS_PIN;

void setup() {

Wire.begin();

Serial.println("SCD30 Raw Data");

scd30.initialize();

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial) {

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

}

void loop() {

if (scd30.isAvailable()) {

scd30.getCarbonDioxideConcentration(result);

Serial.print("Carbon Dioxide Concentration is: ");

Serial.print(result[0]);

Serial.println(" ppm");

}

// make a string for assembling the data to log:

String dataString = "";

// read three sensors and append to the string:

for (int analogPin = 0; analogPin < 3; analogPin++) {

float sensor = result[analogPin];

dataString += String(sensor);

if (analogPin < 2) {

dataString += ",";

}

}

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}Les données sont bien enregistrées sur la carte ! Lorsqu'on souffle sur le capteur, la concentration en CO2 augmente.

Résultats

Dans la suite on essaie de rajouter l'horloge:

Code pour ajouter l'heure

#include <SPI.h>

#include <SD.h>

#include <Wire.h>

#include "SCD30.h"

#include <RTCZero.h>

float result[3] = {0}; // sensor readings

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 16;

const byte day = 23;

const byte month = 1;

const byte year = 24;

void setup() {

Wire.begin();

scd30.initialize();

// Open serial communications and wait for port to open:

Serial.begin(9600);

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

//if (scd30.isAvailable())

scd30.getCarbonDioxideConcentration(result);

Serial.print("Carbon Dioxide Concentration is: ");

Serial.print(result[0]);

Serial.println(" ppm");

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString +=",";

// read three sensors and append to the string:

for (int analogPin = 0; analogPin < 3; analogPin++) {

float sensor = result[analogPin];

dataString += String(sensor);

if (analogPin < 2) {

dataString += ",";

}

}

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(3000);

}On vérifie et les données sont bien enregistrées sur la carte SD !

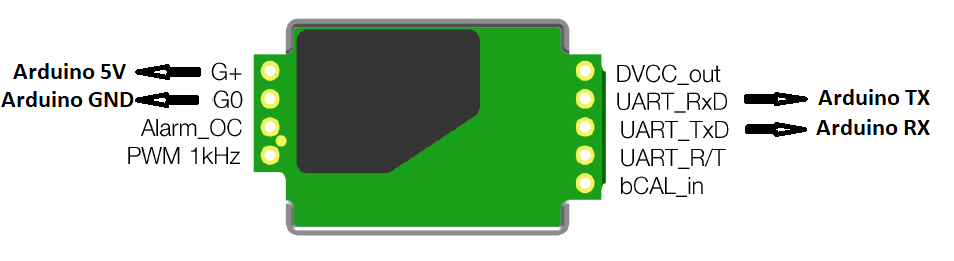

Capteur Sense Air S8 :

https://forum.arduino.cc/t/capteur-de-co2-senseair-s8-code-ultrasimple/1007731

Détails

Code Data logger capteur Sense Air S8

const byte CO2Command[] = {0xFE, 0X04, 0X00, 0X03, 0X00, 0X01, 0XD5, 0XC5};

byte Response[] = {0, 0, 0, 0, 0, 0, 0};

unsigned long val;

void setup() {

Serial1.begin(9600);//Brancher le S8 sur RX1 et TX1

Serial.begin(9600);

delay(100);

Serial.print("start");

}

void loop() {

Serial1.write(CO2Command, 8);

Serial1.readBytes(Response, 7);

while (Serial1.available()) Serial1.read();//vidage du buffer

if (Response[0] == 254) {

val = Response[3] * 256 + Response[4];

Serial.println(val);

}

else Serial.println("erreur CO2");

delay(2000);

}

On obtient des valeurs. Lorsqu'on souffle sur le capteur les valeurs augmentent, on arrive à une saturation à 10000. Le capteur redescends vers 600/700 au repos.

On modifie ensuite le code pour qu'il affiche l'heure et enregistre les données sur la carte SD.

Code datalogger horloge + carte SD SenseAirS8

#include <SD.h>

#include <RTCZero.h>

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 16;

const byte day = 15;

const byte month = 6;

const byte year = 18;

const byte CO2Command[] = {0xFE, 0X04, 0X00, 0X03, 0X00, 0X01, 0XD5, 0XC5};

byte Response[] = {0, 0, 0, 0, 0, 0, 0};

unsigned long val;

void setup() {

Serial1.begin(9600);//Brancher le S8 sur RX1 et TX1

Serial.begin(9600);

delay(100);

Serial.print("start");

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

Serial1.write(CO2Command, 8);

Serial1.readBytes(Response, 7);

while (Serial1.available()) Serial1.read();//vidage du buffer

if (Response[0] == 254) {

val = Response[3] * 256 + Response[4];

Serial.println(val);

}

else Serial.println("erreur CO2");

delay(1000);

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString += " CO2 :";

dataString += String(val);

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}

Capteur MH-Z19B :

https://github.com/nara256/mhz19_uart?tab=readme-ov-file

Pour l'instant les codes testés ne fonctionnent pas ils contiennent notamment la librairie SoftwareSerial qui n'est pas disponible avec la carte MKRZero.

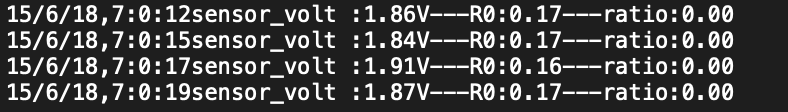

Capteur MQ-9 :

Détails

On commence par récupérer les valeurs de tension du capteur avec le code suivant, inspiré du lien, ci dessus.

Code Capteur MQ-9

// Inclure le code de la bibliothèque:

//#include <LiquidCrystal_I2C.h>

// Initialiser la bibliothèque avec les dimensions de l'interface

//LiquidCrystal_I2C lcd(0x27, 20, 4);

// Capteur MQ-9

// réglage de la broche de connexion

#define pinA A0

// variables de mesure

float sensor_volt;

float RS_air;

float R0;

float sensorValue;

float RS_gas;

float ratio;

unsigned long currentTime = 0;

unsigned long previousTime = 0;

boolean StabilisationMQ9;

char buffer[20] = "";

char buffer2[5] = "";

char buffer3[5] = "";

void setup() {

Serial.begin(9600);

//pinMode(ledPinVert, OUTPUT);

//digitalWrite(ledPinVert, LOW);

//pinMode(ledPinRouge, OUTPUT);

//digitalWrite(ledPinRouge, LOW);

// Initialisation de l'interface LCD

//lcd.init();

// Active le rétro-éclairage du LCD

//lcd.backlight();

}

void loop() {

currentTime = millis();

//Programme stabilisation

if (StabilisationMQ9 == 0) {

if ((currentTime - previousTime) > 600000) {

StabilisationMQ9 = 1;

//previousTime = currentTime;

}

// boucle pour récupérer 100 mesures

sensorValue = 0;

for (int x = 0; x < 100; x++) {

// à chaque exécution on ajoute une nouvelle valeur à la variable

// de l'entrée analogique

sensorValue = sensorValue + analogRead(pinA);

delay(1);

}

// obtient la valeur moyenne

sensorValue = sensorValue / 100.0;

// calcul de la valeur de la tension d'entrée

sensor_volt = sensorValue / 1024 * 5.0;

// calcul de la résistance de l'air

RS_air = (5.0 - sensor_volt) / sensor_volt;

// calcul de la constante R0 - ratio 9.9:1 lu sur le graphique

R0 = RS_air / 9.9;

// affichage des données mesurées sur LCD

//lcd.setCursor(0, 0);

//lcd.print("--Stabilisation--MQ9");

//dtostrf(sensor_volt, 2, 2, buffer2);

sprintf(buffer, "Tens. entree: %5sV", buffer2);

//lcd.setCursor(0, 1);

//lcd.print(buffer);

//dtostrf(R0, 4, 2, buffer2);

sprintf(buffer, "Constante R0 : %5s", buffer2);

//lcd.setCursor(0, 2);

//lcd.print(buffer);

// affichage des données mesurées sur console

Serial.println("Stabilisation en cours");

Serial.print("Tension d'entrée: ");

Serial.print(sensor_volt);

Serial.println("V");

Serial.print("Constante R0 : ");

Serial.println(R0);

Serial.println("------------------");

//digitalWrite(ledPinVert, HIGH);

delay(500);

//digitalWrite(ledPinVert, LOW);

delay(500);

}

//Programme mesure

else {

// lire la valeur de la broche analogique

sensorValue = analogRead(pinA);

// calcule la tension d'entrée

sensor_volt = (float)sensorValue / 1024 * 5.0;

// calcul de la résistance actuelle

RS_gas = (5.0 - sensor_volt) / sensor_volt;

// calcule le rapport de lecture du graphique

ratio = RS_gas / R0;

// affichage des données mesurées sur LCD

//lcd.setCursor(0, 0);

//lcd.print(" -- Mesure -- MQ9");

//dtostrf(sensor_volt, 2, 2, buffer2);

sprintf(buffer, "Tens. entree: %5sV", buffer2);

//lcd.setCursor(0, 1);

//lcd.print(buffer);

//dtostrf(R0, 5, 2, buffer2);

//dtostrf(ratio, 5, 1, buffer3);

sprintf(buffer, "R0:%5s Rs/R0:%5s", buffer2, buffer3);

//lcd.setCursor(0, 2);

//lcd.print(buffer);

// affichage des données mesurées sur console

Serial.println("Stabilisation ok");

Serial.print("Tension d'entrée: ");

Serial.println(sensor_volt);

Serial.print("Constante R0 : ");

Serial.println(R0);

Serial.print("Rapport de Rs/R0: ");

Serial.println(ratio);

Serial.println("------------------ ");

// si le ratio est inférieur à 1,5,

// on calcule l'estimation de la concentration en CO

if (ratio < 1.5) {

//digitalWrite(ledPinRouge, HIGH);

//digitalWrite(ledPinVert, LOW);

// recalcul des données chargées, de la plage 0-700

// à la concentration 200-10000

ratio = ratio * 100;

int ppm = map(ratio, 150, 79, 200, 1000);

sprintf(buffer, "Alarme CO : %d ppm", ppm);

//lcd.setCursor(0, 3);

//lcd.print(buffer);

Serial.print("Concentration approximative de CO : ");

Serial.print(ppm);

Serial.println(" ppm.");

} else {

//digitalWrite(ledPinRouge, LOW);

// digitalWrite(ledPinVert, HIGH);

//lcd.setCursor(0, 3);

//lcd.print(" ");

}

Serial.println();

delay(1000);

}

}

On rajoute maintenant l'horloge et on enregistre les données sur la carte SD. Le code nous affiche bien les valeurs, elles sont également enregistrées sur la carte SD.

Code Horloge + carte SD

// Capteur MQ-9

// réglage de la broche de connexion

#define pinA A0

#include <RTCZero.h>

#include <SD.h>

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 7;

const byte day = 15;

const byte month = 6;

const byte year = 18;

// variables de mesure

float sensor_volt;

float RS_air;

float R0;

float sensorValue;

float RS_gas;

float ratio;

unsigned long currentTime = 0;

unsigned long previousTime = 0;

boolean StabilisationMQ9;

char buffer[20] = "";

char buffer2[5] = "";

char buffer3[5] = "";

void setup() {

Serial.begin(9600);

while (!Serial)

{

;

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

currentTime = millis();

//Programme stabilisation

if (StabilisationMQ9 == 0) {

if ((currentTime - previousTime) > 600000) {

StabilisationMQ9 = 1;

//previousTime = currentTime;

}

// boucle pour récupérer 100 mesures

sensorValue = 0;

for (int x = 0; x < 100; x++) {

// à chaque exécution on ajoute une nouvelle valeur à la variable

// de l'entrée analogique

sensorValue = sensorValue + analogRead(pinA);

delay(1);

}

// obtient la valeur moyenne

sensorValue = sensorValue / 100.0;

// calcul de la valeur de la tension d'entrée

sensor_volt = sensorValue / 1024 * 5.0;

// calcul de la résistance de l'air

RS_air = (5.0 - sensor_volt) / sensor_volt;

// calcul de la constante R0 - ratio 9.9:1 lu sur le graphique

R0 = RS_air / 9.9;

sprintf(buffer, "Tens. entree: %5sV", buffer2);

sprintf(buffer, "Constante R0 : %5s", buffer2);

Serial.println("Stabilisation en cours");

Serial.print("Tension d'entrée: ");

Serial.print(sensor_volt);

Serial.println("V");

Serial.print("Constante R0 : ");

Serial.println(R0);

Serial.println("------------------");

delay(500);

delay(500);

}

//Programme mesure

else {

// lire la valeur de la broche analogique

sensorValue = analogRead(pinA);

// calcule la tension d'entrée

sensor_volt = (float)sensorValue / 1024 * 5.0;

// calcul de la résistance actuelle

RS_gas = (5.0 - sensor_volt) / sensor_volt;

// calcule le rapport de lecture du graphique

ratio = RS_gas / R0;

// affichage des données mesurées sur LCD

//lcd.setCursor(0, 0);

//lcd.print(" -- Mesure -- MQ9");

//dtostrf(sensor_volt, 2, 2, buffer2);

sprintf(buffer, "Tens. entree: %5sV", buffer2);

//lcd.setCursor(0, 1);

//lcd.print(buffer);

//dtostrf(R0, 5, 2, buffer2);

//dtostrf(ratio, 5, 1, buffer3);

sprintf(buffer, "R0:%5s Rs/R0:%5s", buffer2, buffer3);

//lcd.setCursor(0, 2);

//lcd.print(buffer);

// affichage des données mesurées sur console

Serial.println("Stabilisation ok");

Serial.print("Tension d'entrée: ");

Serial.println(sensor_volt);

Serial.print("Constante R0 : ");

Serial.println(R0);

Serial.print("Rapport de Rs/R0: ");

Serial.println(ratio);

Serial.println("------------------ ");

}

// si le ratio est inférieur à 1,5,

// on calcule l'estimation de la concentration en CO

//if (ratio < 1.5) {

// recalcul des données chargées, de la plage 0-700

// à la concentration 200-10000

//ratio = ratio * 100;

//int ppm = map(ratio, 150, 79, 200, 1000);

//sprintf(buffer, "Alarme CO : %d ppm", ppm);

//Serial.print("Concentration approximative de CO : ");

//Serial.print(ppm);

//Serial.println(" ppm.");

//} else {

// ;

//}

//Serial.println();

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString += "sensor_volt :";

dataString += String(sensor_volt);

dataString += "V---";

dataString += "R0:";

dataString += String(R0);

dataString += "---ratio:";

dataString += String(ratio);

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}

Jour 6 : Interprétation des valeurs

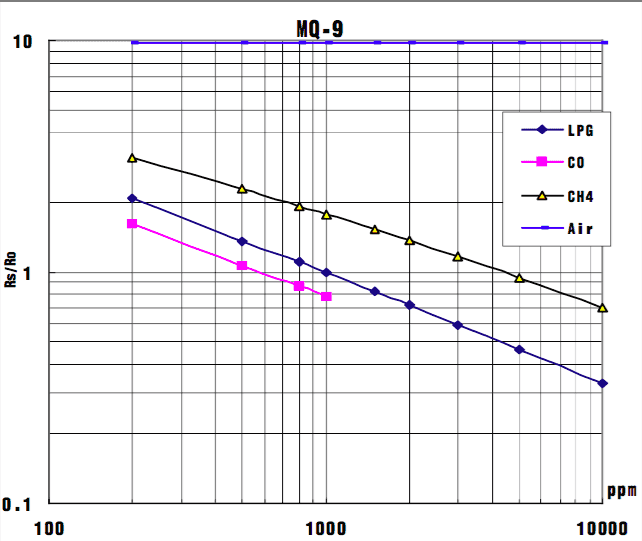

Capteur MQ-9:

https://wiki.seeedstudio.com/Grove-Gas_Sensor-MQ9/

Le premier code nous donne R0 sui sera utilisée dans le code suivant pour calculer le ratio RS/R0.Sur le site du fabricant on obtient le graphique suivant qui nous permet de déduire la concentration d'un gaz en fonction du ratio RS/R0.

Code MQ-9 (R0)

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float RS_air; // Get the value of RS via in a clear air

float R0; // Get the value of R0 via in LPG

float sensorValue;

/*--- Get a average data by testing 100 times ---*/

for(int x = 0 ; x < 100 ; x++)

{

sensorValue = sensorValue + analogRead(A0);

}

sensorValue = sensorValue/100.0;

/*-----------------------------------------------*/

sensor_volt = sensorValue/1024*5.0;

RS_air = (5.0-sensor_volt)/sensor_volt; // omit *RL

R0 = RS_air/9.9; // The ratio of RS/R0 is 9.9 in LPG gas from Graph (Found using WebPlotDigitizer)

Serial.print("sensor_volt = ");

Serial.print(sensor_volt);

Serial.println("V");

Serial.print("R0 = ");

Serial.println(R0);

delay(1000);

}

Code MQ-9

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float RS_gas; // Get value of RS in a GAS

float ratio; // Get ratio RS_GAS/RS_air

int sensorValue = analogRead(A0);

sensor_volt=(float)sensorValue/1024*5.0;

RS_gas = (5.0-sensor_volt)/sensor_volt; // omit *RL

/*-Replace the name "R0" with the value of R0 in the demo of First Test -*/

ratio = RS_gas/R0; // ratio = RS/R0

/*-----------------------------------------------------------------------*/

Serial.print("sensor_volt = ");

Serial.println(sensor_volt);

Serial.print("RS_ratio = ");

Serial.println(RS_gas);

Serial.print("Rs/R0 = ");

Serial.println(ratio);

Serial.print("\n\n");

delay(1000);

}

Capteur MQ-2 :

https://wiki.seeedstudio.com/Grove-Gas_Sensor-MQ2/

Le code utilisé jusqu'ici affichait des valeurs pour trois gaz différents.

Les code MQ2 (R0) nous permet d'établir la concentration R0 qui sera utilisée dans le code suivant qui nous donne la valeur RS/R0. On peut retrouver la concentration avec le graphe.

Code MQ2 (R0)

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float RS_air; // Get the value of RS via in a clear air

float R0; // Get the value of R0 via in H2

float sensorValue;

// Get a average data by testing 100 times

for(int x = 0 ; x < 100 ; x++)

{

sensorValue = sensorValue + analogRead(A0);

}

sensorValue = sensorValue/100.0;

sensor_volt = sensorValue/1024*5.0;

RS_air = (5.0-sensor_volt)/sensor_volt; // omit * RL

R0 = RS_air/9.8; // The ratio of RS/R0 is 9.8 in a clear air from Graph (Found using WebPlotDigitizer)

Serial.print("sensor_volt = ");

Serial.print(sensor_volt);

Serial.println("V");

Serial.print("R0 = ");

Serial.println(R0);

delay(1000);

}

Code MQ2 (valeurs)+ horloge + carte SD

#include <SD.h>

#include <RTCZero.h>

const int chipSelect = SDCARD_SS_PIN;

#define PIN A0;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 16;

const byte day = 15;

const byte month = 6;

const byte year = 18;

void setup() {

Serial.begin(9600);

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

float sensor_volt;

float RS_gas; // Get value of RS in a GAS

float ratio; // Get ratio RS_GAS/RS_air

int sensorValue = analogRead(A0);

sensor_volt=(float)sensorValue/1024*5.0;

RS_gas = (5.0-sensor_volt)/sensor_volt; // omit * RL

/*-Replace the name "R0" with the value of R0 in the demo of First Test -*/

ratio = RS_gas/0.17; // ratio = RS/R0 //0.17=R0

/*-----------------------------------------------------------------------*/

Serial.print("sensor_volt = ");

Serial.println(sensor_volt);

Serial.print("RS_ratio = ");

Serial.println(RS_gas);

Serial.print("Rs/R0 = ");

Serial.println(ratio);

Serial.print("\n\n");

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString += "sensor_volt = ";

dataString += String(sensor_volt);

dataString += "RS_ratio = ";

dataString += String(RS_gas);

dataString += "Rs/R0 = ";

dataString += String(ratio);

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}

Capteur SCD30 :

Ce capteur affiche la concentration de CO2 en ppm.

Capteur SenseAir S8 :

Ce capteur affiche la concentration de CO2 en ppm.

Update : On a pu récupérer la tourbe à l'espace biologie. On a trouvé une boite un peu grande pour mettre la terre. Il faudra qu'on y retourne pour le deuxième type de terre.

Jour 7 : Comparaison des capteurs

On programme 2 capteurs Sense air S8 et 2 capteurs SCD30 qu'on dispose dans une boîte (pas très étanche). On souffle dans la boîte puis on la referme. On attends 10min et on récupère les cartes SD.

Résultats :

- SCD30 n°1 : Aucune valeur n’a été enregistrée sur la carte

- SCD30 n°2 : La même valeur est enregistré sur la carte à partir du moment ou la carte est déconnectée de l'ordinateur.

- Sense Air n°1 : La même valeur est enregistré sur la carte à partir du moment ou la carte est déconnectée de l'ordinateur.

- Sense Air n°2 : La même valeur est enregistré sur la carte à partir du moment ou la carte est déconnectée de l'ordinateur.

Conclusion : On pense que les batteries ne sont pas chargées, pour le premier capteur peut-être que la carte SD était mal placée.

On laisse charger les batteries puis on recommence la même expérience.

Résultats :

- SCD30 n°1 : Aucune valeur n’a été enregistrée sur la carte

- SCD30 n°2 : Des valeurs sont enregistrés sur la carte jusqu’à 10min après le début de l'expérience puis plus rien.

- Sense Air S8 n°1 : La même valeur est enregistré sur la carte jusqu’à la fin de l'expérience.

- Sense Air S8 n°2 : La même valeur est enregistré sur la carte jusqu’à la fin de l'expérience.

On recharge les batteries et on place cette fois-ci 2 les capteurs SCD30 et 3 capteurs MQ-2:

Résultats :

- SCD30 n°1 : Aucune valeur n'est enregistrée.

- SCD30 n°2 : Les valeurs n'ont pas été enregistrées (dernière valeur est celle de l'expérience d'avant).

- MQ2 n°1 : Les valeurs s'enregistrent bien sur la carte.

- MQ2 n°2 : Les valeurs s'enregistrent bien sur la carte.

- MQ2 n°3 : Les valeurs s'enregistrent bien sur la carte.

On a eu l'aide de M.Simon avec les codes suivants qui permettent à la carte de détecter si elle est branchée à l'ordi ou non, afin d'éviter la boucle while si non. Il faut donc brancher un cable entre le port 6 et 5V quand la carte n'est branché pas l'ordi.

Autre code pour le SCD30

#include <SPI.h>

#include <SD.h>

#include <Wire.h>

#include "SCD30.h"

#include <RTCZero.h>

float result[3] = {0}; // sensor readings

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 0;

const byte hours = 15;

const byte day = 23;

const byte month = 1;

const byte year = 24;

int modeButton = 6; // Choix connecte/deconnecte

void setup() {

Wire.begin();

scd30.initialize();

pinMode(modeButton, INPUT);

bool connectedMode = digitalRead(modeButton);

if(connectedMode) {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while(!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

//if (scd30.isAvailable())

scd30.getCarbonDioxideConcentration(result);

Serial.print("Carbon Dioxide Concentration is: ");

Serial.print(result[0]);

Serial.println(" ppm");

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString +=",";

// read three sensors and append to the string:

for (int analogPin = 0; analogPin < 3; analogPin++) {

float sensor = result[analogPin];

dataString += String(sensor);

if (analogPin < 2) {

dataString += ",";

}

}

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(3000);

}

Code pour Sense 8

#include <SD.h>

#include <RTCZero.h>

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 1;

const byte hours = 16;

const byte day = 23;

const byte month = 1;

const byte year = 24;

int modeButton = 6; // Choix connecte/deconnecte

const byte CO2Command[] = {0xFE, 0X04, 0X00, 0X03, 0X00, 0X01, 0XD5, 0XC5};

byte Response[] = {0, 0, 0, 0, 0, 0, 0};

unsigned long val;

void setup() {

Serial1.begin(9600);//Brancher le S8 sur RX1 et TX1

Serial.begin(9600);

delay(100);

Serial.print("start");

pinMode(modeButton, INPUT);

bool connectedMode = digitalRead(modeButton);

if(connectedMode) {

while (!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

// make a string for assembling the data to log:

String dataString = "";

Serial1.write(CO2Command, 8);

Serial1.readBytes(Response, 7);

while (Serial1.available()) Serial1.read();//vidage du buffer

if (Response[0] == 254) {

val = Response[3] * 256 + Response[4];

Serial.println(val);

}

else Serial.println("erreur CO2");

delay(1000);

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString += " CO2 :";

dataString += String(val);

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(1000);

}

Jour 8 : TESTS

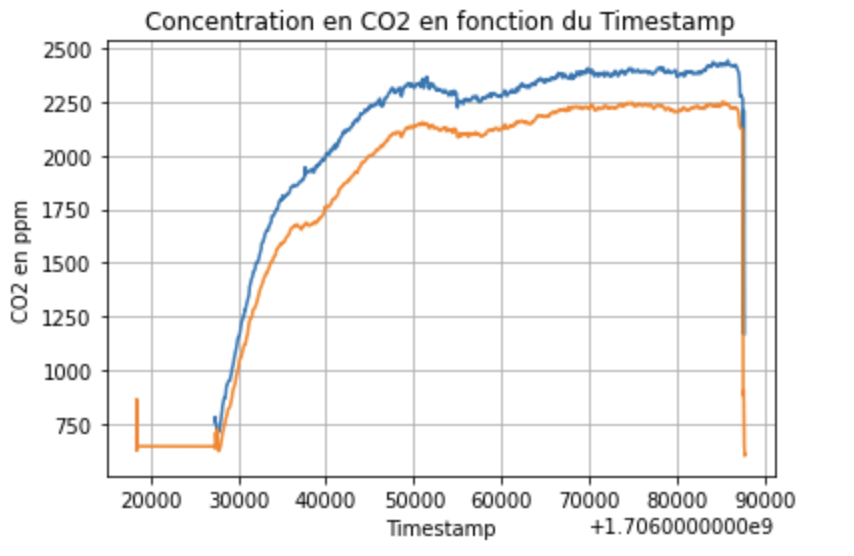

On reprogramme deux capteurs SCD30 qu'on place dans la boîte, on souffle et on referme. On obtient les valeurs pour les deux capteurs. On observe une augmentation de la concentration lorsqu'on souffle puis une diminution due aux fuites. On cherche maintenant à tracer les valeurs obtenues.

On relance une acquisition dans la boîte, cette fois-ci avec la tourbe à l'intérieure. On ajoute au code un timestamp pour avoir le temps écoulé sous un format utilisable dans python.

Code timestemp

#include <SPI.h>

#include <SD.h>

#include <Wire.h>

#include "SCD30.h"

#include <RTCZero.h>

float result[3] = {0}; // sensor readings

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 1;

const byte hours = 14;

const byte day = 23;

const byte month = 1;

const byte year = 24;

int modeButton = 6; // Choix connecte/deconnecte

void setup() {

Wire.begin();

scd30.initialize();

pinMode(modeButton, INPUT);

bool connectedMode = digitalRead(modeButton);

if(connectedMode) {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while(!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");

Serial.print(rtc.getMonth());

Serial.print("/");

Serial.print(rtc.getYear());

Serial.print(" ");

Serial.print(rtc.getHours());

Serial.print(":");

Serial.print(rtc.getMinutes());

Serial.print(":");

Serial.print(rtc.getSeconds());

Serial.println();

Serial.print(rtc.getEpoch());

// make a string for assembling the data to log:

String dataString = "";

//if (scd30.isAvailable())

scd30.getCarbonDioxideConcentration(result);

Serial.print("Carbon Dioxide Concentration is: ");

Serial.print(result[0]);

Serial.println(" ppm");

dataString += String(rtc.getDay());

dataString +="/";

dataString += String(rtc.getMonth());

dataString +="/";

dataString += String(rtc.getYear());

dataString +=",";

dataString += String(rtc.getHours());

dataString +=":";

dataString += String(rtc.getMinutes());

dataString +=":";

dataString += String(rtc.getSeconds());

dataString +=",";

dataString += String(rtc.getEpoch());

dataString +=",";

// read three sensors and append to the string:

for (int analogPin = 0; analogPin < 3; analogPin++) {

float sensor = result[analogPin];

dataString += String(sensor);

if (analogPin < 2) {

dataString += ",";

}

}

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File dataFile = SD.open("datalog.txt", FILE_WRITE);

// if the file is available, write to it:

if (dataFile) {

dataFile.println(dataString);

dataFile.close();

// print to the serial port too:

Serial.println(dataString);

}

// if the file isn't open, pop up an error:

else {

Serial.println("error opening datalog.txt");

}

delay(3000);

}

On a lancé une acquisition pour la nuit à 16h36 avec le code ci-dessus.

Jour 9: Résultats

On récupère les données des cartes SD. Grâce à python on trace l'évolution de la concentration de CO2 en fonction du timestamp. Notre échantillon de terre pèse 1789g.

Code pyhton

import matplotlib.pyplot as plt

import pandas as pd

import numpy as np

#lit les fichiers DATALOG

data_1 = pd.read_csv("SCD30 _TERRE_1.TXT")

data_2 = pd.read_csv("SCD30_TERRE_2.TXT")

#print(data_1)

#print(data_2)

#extrait les colonnes "timestamp" des fichiers

timestamp_1 = np.array(data_1[" timestamp"])

timestamp_2 = np.array(data_2[" timestamp"])

#extrait les colonnes "CO2"

CO2_1 =np.array(data_1[' CO2'])

CO2_2 =np.array(data_2[' CO2'])

#trace le CO2 en fonction du timestamp

plt.plot(timestamp_1, CO2_1, label='capteur 1')

plt.plot(timestamp_2, CO2_2, label='capteur 2')

#plt.xlim(2500*10^9,9000*10^9)

plt.xlabel("Timestamp")

plt.ylabel("CO2 en ppm")

plt.title("Concentration en CO2 en fonction du Timestamp")

plt.grid()

plt.legend

plt.show()

ON obtient le graphique suivant :

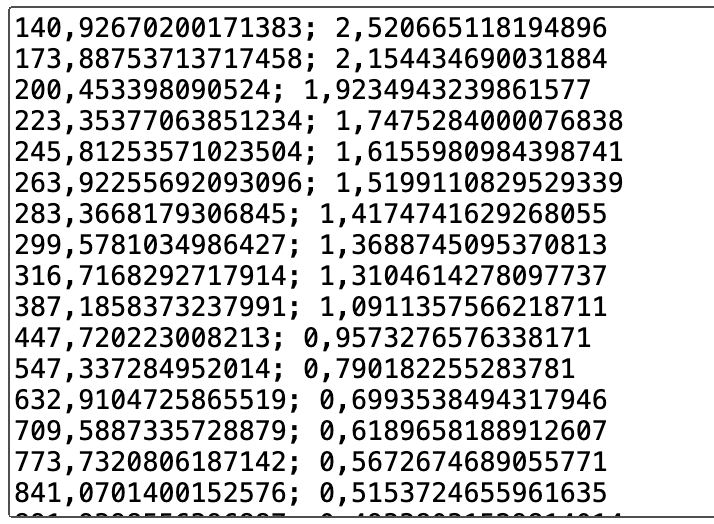

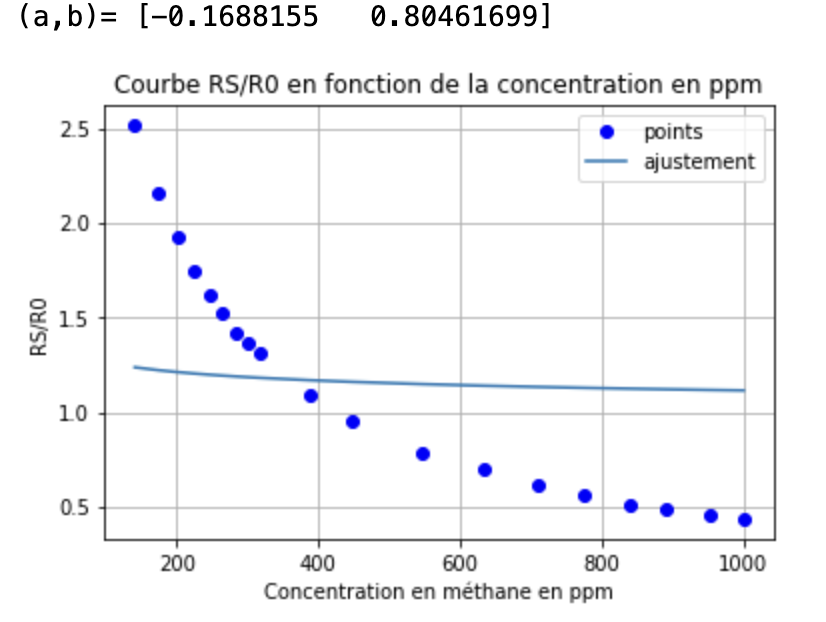

On cherche maintenant à observer la production de méthane par le sol. On utilise les codes suivants pour initialiser la valeur de R0, puis pour obtenir le ratio RS/R0 qui nous permettra de retrouver la concentration en gas grâce au graphique fournit.

Code R0

void setup() {

Serial.begin(9600);

}

void loop() {

float sensor_volt;

float RS_air; // Get the value of RS via in a clear air

float R0; // Get the value of R0 via in LPG

float sensorValue;

/*--- Get a average data by testing 100 times ---*/

for(int x = 0 ; x < 100 ; x++)

{

sensorValue = sensorValue + analogRead(A0);

}

sensorValue = sensorValue/100.0;

/*-----------------------------------------------*/

sensor_volt = sensorValue/1024*5.0;

RS_air = (5.0-sensor_volt)/sensor_volt; // omit *RL

R0 = RS_air/9.9; // The ratio of RS/R0 is 9.9 in LPG gas from Graph (Found using WebPlotDigitizer)

Serial.print("sensor_volt = ");

Serial.print(sensor_volt);

Serial.println("V");

Serial.print("R0 = ");

Serial.println(R0);

delay(1000);

}

Code RS/R0

#include <RTCZero.h>

#include <SPI.h>

#include <Wire.h>

#include <SD.h>

const int chipSelect = SDCARD_SS_PIN;

/* Create an rtc object */

RTCZero rtc;

const byte seconds = 0;

const byte minutes = 1;

const byte hours = 14;

const byte day = 23;

const byte month = 1;

const byte year = 24;

int modeButton = 6; // Choix connecte/deconnecte

void setup() {

Serial.begin(9600);

pinMode(modeButton, INPUT);

bool connectedMode = digitalRead(modeButton);

if(connectedMode) {

// Open serial communications and wait for port to open:

Serial.begin(9600);

while(!Serial)

{

; // wait for serial port to connect. Needed for native USB port only

}

}

Serial.print("Initializing SD card...");

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println("Card failed, or not present");

// don't do anything more:

while (1);

}

Serial.println("card initialized.");

rtc.begin(); // initialize RTC

rtc.setHours(hours);

rtc.setMinutes(minutes);

rtc.setSeconds(seconds);

rtc.setDay(day);

rtc.setMonth(month);

rtc.setYear(year);

}

void loop() {

Serial.print(rtc.getDay());

Serial.print("/");